Selection of coverings depending on altitude

The use of SDA 4 is not equally sensible and sustainable at every altitude. The acoustic effectiveness and lifespan of SDA 4 behave differently over time depending on the height and age at different rates. The main causes of accelerated aging of SDA 4 at high altitudes lie in the increased mechanical stresses. These arise particularly from the use of snow removal vehicles as well as from the use of snow chains and spike tires during the winter months. Additionally, in high-altitude regions, intense frost-thaw cycles occur, which can lead to micro-cracks and progressive damage to the grain structure due to the repeated infiltration and freezing of water.

Another critical factor is the climate-related necessity to use bitumen with a higher penetration grade (softer bitumen) at greater altitudes to ensure low-temperature flexibility. However, this reduces resistance to mechanical stresses and promotes deformation and early damage to the surface. For these reasons, the use of SDA is discouraged as soon as softer bitumen becomes necessary due to the altitude.

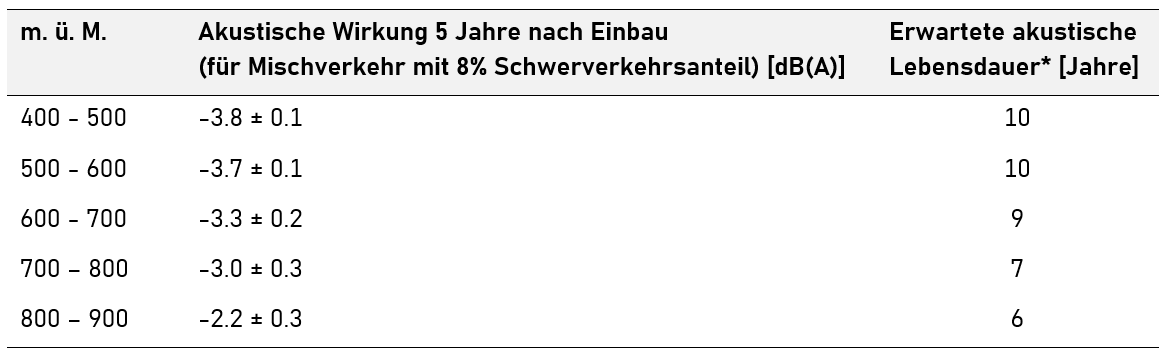

The following table shows how the acoustic effect of SDA 4 changes with increasing altitude. The basis for this information is all SDA 4 measured by Grolimund + Partner AG in Switzerland.

Acoustic surface effect 5 years after installation and the expected lifespan based on all SDA 4 surfaces measured in Switzerland by Grolimund + Partner AG, data per altitude category m. ü. M.]

*expected acoustic lifespan: the point at which the acoustic surface quality value of -3 dB(A) (with 1 dB(A) tolerance) is exceeded in deviation from the model StL-86+.

When the acoustic lifespan of a surface is reached, the technical condition of the surface can, according to experience, allow for an additional operational period of another 2-3 years before the surface layer needs to be replaced.

If a significantly reduced lifespan must be assumed due to the altitude, the use of SDA 4 surfaces should be examined in more detail; if necessary, more robust variants such as SDA 8 or AC 8 should be used to ensure sufficient resistance and avoid a reduction in lifespan.