Acoustic maintenance

With a well-designed mixture and appropriate maintenance measures, the lifespan of SDA surfaces can be extended. Possible maintenance measures for prolonging lifespan include cleaning and grinding (milling or sanding) of the top surface layer. The optimal time for a maintenance measure can be determined through regular monitoring measurements.

| Measure | Expected Effect* | Expected Extension of Acoustic Lifespan | Influencing Factors |

| Cleaning | -1 to -2.5 dB(A) | up to 3 years | Cleaning cycle, depth of dirt penetration, type of dirt |

| Grinding | -2 to -4 dB(A) | 2 to 4 years | Depth of dirt penetration |

*Expected effect based on the current state of knowledge.

Cleaning

In preventive cleaning of surfaces, the goal is to keep the pores of the noise-reducing surface as free from contamination as possible to prevent clogging, which is a major aging factor for noise-reducing surfaces. Regular cleaning measures can positively influence the acoustic properties of noise-reducing surfaces and extend their lifespan.

Various tests for cleaning noise-reducing surfaces have shown that cleaning methods are particularly effective in the top layer of the SDA surface and can effectively remove dirt that is not deeply embedded. Improvements in acoustic effectiveness can only be observed in surfaces that are superficially dirty. In these cases, an improvement of up to 2.5 dB(A) is possible. If the surface is already dirty in the deeper layers, the improvement in acoustic quality is less than 1 dB(A). 1 The effectiveness of cleaning is therefore higher in the first years after paving (National Cooperative Highway Research Program, Transportation Research Board, and National Academies of Sciences, Engineering, and Medicine, 2009)2 .

To prevent/delay the settling of dirt in the surface, cleaning measures should be carried out as early as possible after installation, according to previous experiences. It has also been shown that regular (e.g., quarterly) cleaning pays off.

The cleanings are carried out with special surface cleaning machines that have a rear suction system. The water applied to the road can thus be sucked back. Only in this way can the softened dirt in the upper layer of the surface be effectively removed. In principle, two different cleaning methods are available: front washing beam with rear suction system and Rotocleaner/Rotoplast.

Various cantons apply cleaning measures as part of test projects or already on a large scale.

Follow-up cleaning of noise-absorbing surfaces - results of the 2022 campaign (PDF, 16 MB)

Learn more about the cleaning machines

Front washing beam with rear suction system: Using a front washing beam, water is sprayed onto the road surface at low pressure in front of the cleaning vehicle. The goal is to soften the contamination on and in the surface so that in a second pass, the water along with the dirt can be sucked up. Ideally, cleaning is done after a rain period. In that case, watering can also be omitted. In summary, it can be said that a well-soaked surface and high suction power yield good results.

Rotocleaner/Rotoplast: In this method, the dirt must also be softened by wetting the road surface or precipitation. To better remove embedded dirt, the surface is cleaned with high pressure over a width of about 2.5 m immediately before the rear suction system. The Rotocleaner usually has eight rotors, each with two nozzles. Experience has shown that it should not be set higher than 250 bar, as this increases the risk of aggregate breakage.

Surface cleaning machine in operation. Front washing beam (top) and rear suction system with (bottom left) and without (bottom right) Rotocleaner.

Especially in rural areas, the entry of dirt and thus the acoustic effect can be significantly influenced by agriculture. Similarly, at construction sites directly adjacent to an SDA surface, increased dirt entry can often not be avoided. In both cases, there is a rapid clogging of the surface pores and thus a loss of acoustic effectiveness.

Grinding (Micro-milling)

Grinding – that is, the controlled sanding of the surface – has established itself in recent years as an effective measure for the acoustic regeneration of noise-reducing semi-dense asphalts (SDA). Analyses of 17 Swiss test sections showed significant improvements in the acoustic quality of SDA 4 and SDA 8 surfaces can be achieved through grinding measures.

- SDA 4 surfaces: initial improvement of about –2 to –3 dB(A)

- SDA 8 surfaces: average improvement of –3 dB(A)

- Improvements of around –2 dB(A) have also been observed in dense surfaces (AC 11, ACMR 11, MA 11)

Thus, grinding can contribute to noise reduction not only in noise-reducing surfaces but also in denser surfaces.

Durability of the Effect

The previous monitoring data (up to 4 years) show a sustainable effect of the grinding measure:

|

Surface Type |

Initial Effect |

Durability (vs. Initial State) |

Durability (vs. Reference Section) |

|

SDA 4 |

–2.5 ± 1.0 dB(A) |

2–4 years |

> 4 years |

|

SDA 8 |

–3.1 ± 0.3 dB(A) |

2–4 years |

> 4 years |

|

AC/MA 11 |

–1.9 ± 0.6 dB(A) |

~ 4 years |

> 4 years |

On average, the acoustic initial state is reached again after about three years. However, compared to unground sections, a positive acoustic effect remains for at least four years.

Neither early grinding (e.g., in Farvagny, FR) nor repeated applications, had negative effects on the mechanical stability or pore structure of the surfaces.

Influencing Factors on Effectiveness

The effectiveness of grinding strongly depends on the initial condition of the surface:

- In intact, new surfaces with already very good acoustics (e.g., –7 dB(A)), only a slight improvement is possible.

- In clogged or aged SDA surfaces, grinding can achieve significant improvements through texture optimization and possibly by exposing pores.

Grinding Depth:

- An increased grinding depth increases the chance of reopening pores (“breaking through the dirt barrier”).

- Good results have also been achieved with low grinding depths (1–2 mm) – for example, in La Verrerie (1 mm) and Tafers (1.8 mm) with around 3 dB(A) improvement each.

- In other cases (e.g., Zofingen), low grinding depths worked less well – here, the choice of tool played a decisive role.

Surface Types:

- In dense surfaces, a greater grinding depth provides no additional benefit, as no pore spaces can be exposed.

- In porous SDA 4 surfaces, however, targeted, slightly deeper grinding can significantly improve acoustic effectiveness.

Mechanisms of Action

Grinding influences two central properties of the surface 1 :

- Texture optimization:

- Grinding compensates for unevenness and aggregate breakage.

- A more homogeneous, finer macro- and micro-texture is created, which reduces rolling noise.

- This effect occurs even at low grinding depths and is relevant for all surface types.

- Pore exposure:

- In porous surfaces, grinding can reopen the closed pore structure.

- This leads to better acoustic properties, especially in the mid to high frequency range.

- The improved air pore conditions are also evident in permeability and air void measurements.

Recommendations for Practice

- Principle: Grinding is suitable as an effective maintenance measure for practically all surface types.

- Regeneration Duration:

- For SDA 4 and SDA 8 surfaces, the average acoustic regeneration duration is about 3 years,

but the positive effect remains measurable for over 4 years. - For dense surfaces (11 mm), the effect can last 4 years or longer.

- Goal Definition Before the Measure:

- Should the texture be optimized or the pore structure reopened?

- For 4 mm surfaces, a greater grinding depth may be sensible to open pores.

- For 8 and 11 series surfaces, grinding depths > 3 mm are not advisable.

- Tool Selection: Appropriate grinding tools are crucial for acoustic success.

Grinding is an efficient, cost-effective, and sustainable method to maintain or regenerate the acoustic performance of semi-dense asphalts. With proper planning – especially considering the type of surface, grinding depth, and objectives – the acoustic lifespan of an SDA surface can be extended by at least three years without compromising structural integrity.

To better estimate the optimal removal depth of micro-milling, it is also beneficial to know the depth of contamination. The AVCA methodology is also suitable for this application.

The durability of this effect is currently the subject of ongoing research; initial reliable results on long-term effects are expected in the coming years. The current state of research is described here --> Grinding of noise-reducing surfaces in Switzerland - Insights from monitoring until 2023 (PDF, 34 MB, 15.04.2024) Commissioned by BAFU

Decision Cleaning or Grinding

For effective acoustic maintenance, knowledge about the penetration depth and the exact location of dirt particles as well as the condition of the surface structure is essential. The AVCA methodology is available for this purpose.

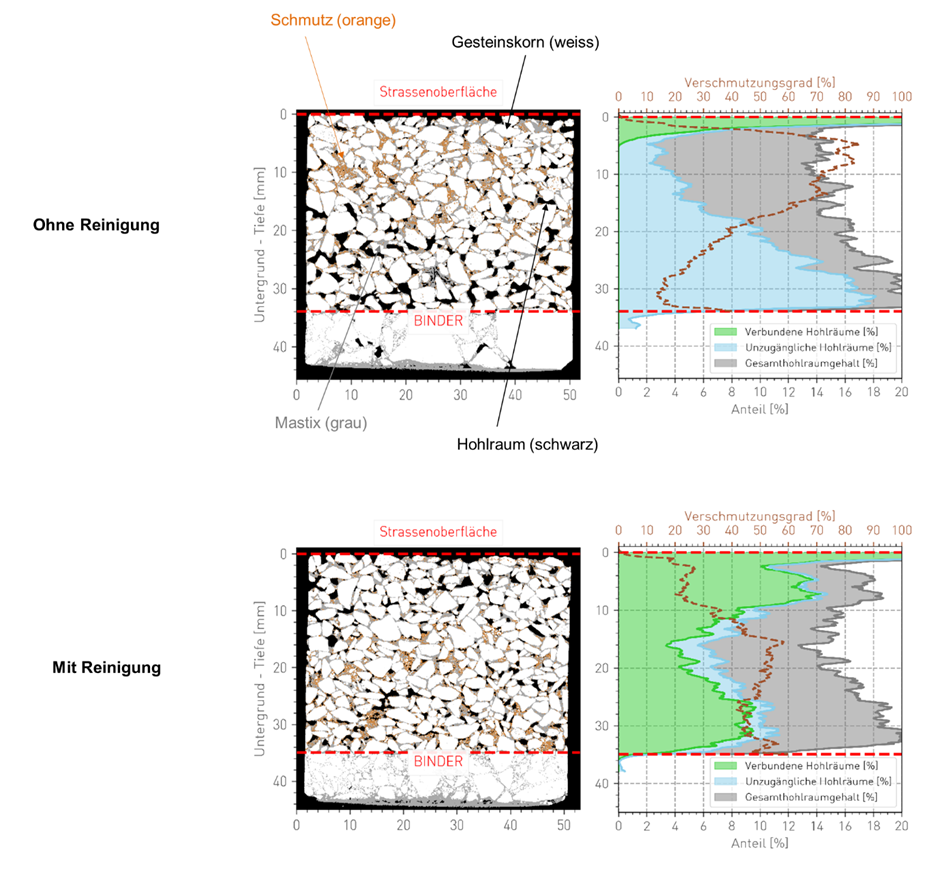

The Acoustic Void Content Analysis (AVCA) method uses a CT scan of a core sample of the SDA surface and generates a 3D model from it. In the model, the dirt can then be accurately located, and its effects on the effective pore structure and acoustics can be predicted.

Cross-sectional profiles (CT scans, left) and corresponding AVCA evaluation (right) of two core samples from a study site. In the uncleaned section, the voids are heavily contaminated in the first approximately 20 mm (brown line), consequently, the pore volumes are mostly closed. In the cleaned section, the degree of contamination in the top layer is significantly lower, and the existing voids are mostly interconnected (green area). (Source: Grolimund + Partner AG)

Chemical Cleaning

In the canton of AG, the use of chemical cleaning is currently being tested on a test track.

Surface Renewal

The aging of bitumen in porous and semi-dense surfaces is more severe due to the larger surface area exposed to oxidation (Jing et al., 2019)2 . This makes the surfaces particularly susceptible to aggregate breakage (Zhang et al., 2016)3 . The use of polymer-modified bitumen in the mixture can partially compensate for this.

Surface treatments, such as spraying asphalt rejuvenators, are used to extend the lifespan of dense surfaces. In the Netherlands, products to extend the lifespan of a surface have been used since 2010, primarily preventively at the first occurrence of aggregate breakage, about 5 to 7 years after installation. However, the surface must not be seriously damaged at that time. The lifespan of the surface layers can subsequently be increased by 2 to 4 years. Only one treatment is recommended per surface layer. The treatment involves cold bitumen emulsions that contain rejuvenators or a warm-applied polymer-modified bitumen. The products are applied with a pressure blower (PA surfaces) or with a spray bar (thin-layer surfaces), where they penetrate 10 to 20 mm into the layer through dents and pores (Saurer, Bühlmann and Ziegler, 2016)4 .

As with porous surfaces, the application of the rejuvenator to the bitumen of SDA surfaces can have negative effects, as it can close the pore structure, even if the bitumen is rejuvenated.

The penetration depth and the resulting rejuvenation effect in SDA surfaces have not yet been tested.