Mixed production

The production of SDA mixtures in the asphalt mixing plant (see figure) differs from conventional asphalt mixtures, particularly due to the higher requirements for maintaining the grain distribution to ensure the desired void content.

Typically, polymer-modified bitumen PmB 45/80-65 E is used. The mixing temperature is usually around 170 °C, and the aggregates used must also be preheated to this temperature. The mixing plant must be technically equipped for processing PmB accordingly.

Asphalt mixing plant in Switzerland (Source: Ammann Group)

The following gravel fractions are used to produce SDA mixtures:

-

For SDA 4, gravel fractions of 2/4 mm, 0/2 mm, and filler are typically used.

-

For SDA 8, the fraction 4/8 mm is additionally used.

During production, regular quality control of the materials is essential and is also mandatory according to SN EN 13108-21 (VSS, 2021f).

Further details on these requirements are explained in the chapter Success control of aggregates.

Experiences in mixture production

Challenges in the Marshall test

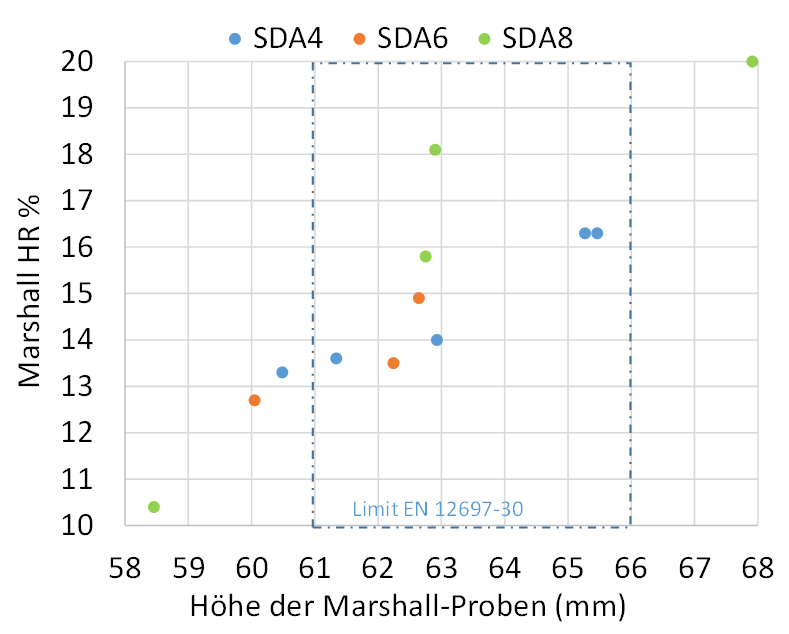

A central problem in the Marshall tests is the influence of the sample height and mass on the test results. According to EN 12697-30 (“Bituminous mixtures – Test method for hot mix asphalt – Part 30: Specimen preparation by impact compactor”, 2019), samples with a diameter of 101.6 ± 0.1 mm and a height of 63.5 ± 2.5 mm are required.

-

The tolerance in diameter is very small, as it is determined by the steel shaping. As long as the sample is not removed from the mold too early (i.e., while still hot and moldable), this dimensional accuracy is maintained.

-

The height, on the other hand, is influenced by the person executing the process – based on an estimated initial mass derived from the maximum relative density of the mixture according to EN 12697-5 (VSS, 2020).

Based on the standard height (63.5 mm) and a target void content of 15%, a target mass of 1.083 kg would result. Depending on the actual height achieved between 61 and 66 mm, this would lead to a mass deviation of 1.041–1.125 kg. These mass differences affect the compaction energy, as a lower weight proportionally introduces more energy into the sample. If the mass is kept constant, this can lead to void contents between 11.5 and 18.2% – although this does not hold true in practice, as the degree of compaction reacts oppositely (more voids = stronger compaction and vice versa).

A significant part of the problem was that the sample heights were outside the permissible range of 61–66 mm. To avoid this, it was recommended to align the sample height as precisely as possible to 63.5 mm. From these findings, the recommendation arises to reduce the tolerance limit to ±1 mm.

This issue affects not only the laboratory – as SDA mixtures are also produced in practice according to the same quality standards.

Marshall-HR% compared to the average heights of the samples (Mikhailenko et al., 2024)(Poulikakos et al., 2024).1

Requirements and evaluation of binders

The selection of the binder used – particularly type and manufacturer – is usually made according to standardized specifications. In practice, however, the exact origin of the binder is often not traceable.

Traditionally, ring and needle tests have been conducted, which are conditionally suitable for polymer-modified bitumen (PmB). Other important properties, such as elastic recovery or behavior under temperature stress, are not yet systematically evaluated.

A promising approach for better assessing binder quality is viscosity measurement at various temperatures. This would allow for a more precise statement about the performance of the binder. However, there are currently no concrete standard requirements or specifications in the tenders from clients.

The canton of Zurich has already introduced binding specifications for the bitumen used.

Performance of highly modified bitumen (HiMa)

The bitumen commonly used in SDA pavements is PmB 45/80-65. A recent ASTRA study investigated the use of highly modified PmB 45/80-80 (HiMa) for SDA 4, 6, and 8 (Poulikakos et al., 2024).2

The results showed improved water sensitivity and higher fatigue resistance compared to conventional PmB 45/80-65. This confirms earlier studies showing that polymer modifications significantly improve the mechanical properties of bitumen (Ali & Siddiqui, 2001)3.

However, the cost implications of using highly modified bitumen are not yet conclusively clarified – especially since mechanical durability issues in SDA pavements have not been documented so far. In comparison, in the Netherlands, no PmB is used in open-graded asphalt, which is also favored by the milder winter climate (Opzetten Asfaltkwaliteitsloket, 2018)4.

However, the use of a more efficient bitumen could help increase the durability of SDA pavements.

The responsibility for the correct binder content lies with the respective mixing plant, which must ensure that the produced mixtures meet the normative requirements.